A 3 part asynchronous motor, generally referred to as an induction motor, is a sort of electrical motor that operates on the ideas of electromagnetic induction. It’s known as “asynchronous” as a result of the rotor doesn’t rotate on the identical velocity because the magnetic discipline produced by the stator, a phenomenon referred to as “slip.” These motors are extensively utilized in industrial and business purposes as a consequence of their robustness, reliability, and effectivity.

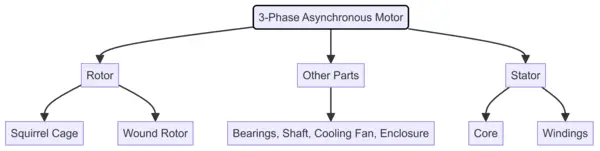

Primary Parts and Working Precept

- Stator: The stationary a part of the motor, which produces the rotating magnetic discipline. It consists of a core product of laminated metal and windings that carry the three part present.

- Rotor: The rotating a part of the motor, which is positioned contained in the stator. The rotor will be of two sorts: squirrel cage or wound (slip ring).

- Different Components: Bearings, shaft, cooling fan, and enclosure are extra parts that guarantee easy operation and sturdiness.

Working Precept

The operation of a 3 part asynchronous motor relies on the precept of electromagnetic induction. When a 3 part present flows by means of the stator windings, it creates a rotating magnetic discipline. This discipline induces a present within the rotor, producing a magnetic discipline that interacts with the stator’s discipline. The interplay of those magnetic fields generates a torque that causes the rotor to show, thereby changing electrical vitality into mechanical vitality.

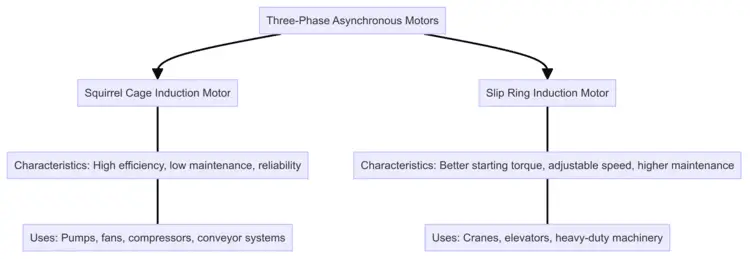

Kinds of Three-Section Asynchronous Motors

Three-phase asynchronous motors are available two main sorts: squirrel cage induction motors and slip ring induction motors.

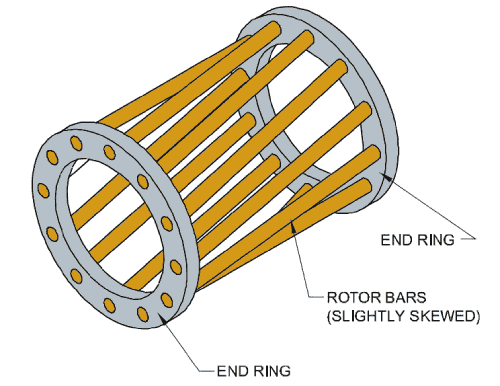

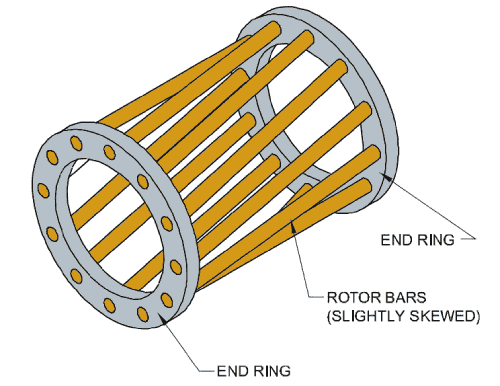

Squirrel Cage Induction Motor

The squirrel cage induction motor is the commonest kind, identified for its easy and rugged building. It contains a rotor product of conductive bars short-circuited by finish rings, resembling a squirrel cage. These motors are extensively utilized in purposes the place a continuing velocity is required.

- Traits: Excessive effectivity, low upkeep, and reliability.

- Makes use of: Pumps, followers, compressors, and conveyor methods.

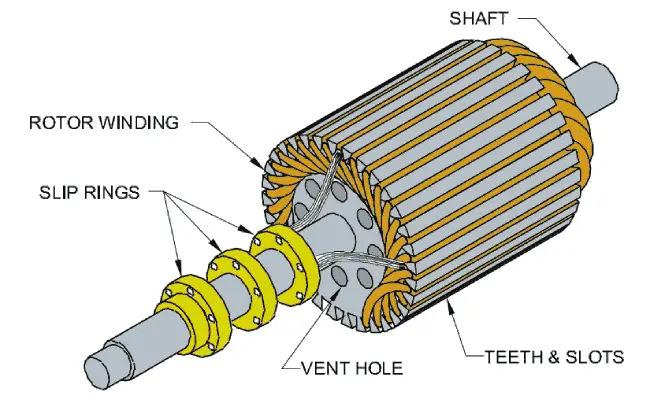

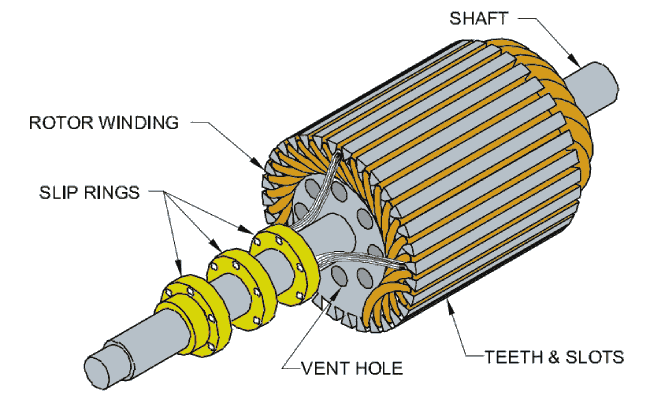

Slip Ring Induction Motor

The slip ring induction motor, also referred to as a wound rotor motor, has a rotor with windings related to slide rings. This design permits for exterior resistance to be added to the rotor circuit, offering higher management over the motor’s beginning and working traits.

- Traits: Higher beginning torque, adjustable velocity, and better upkeep necessities.

- Makes use of: Cranes, elevators, and heavy-duty equipment requiring variable velocity management.

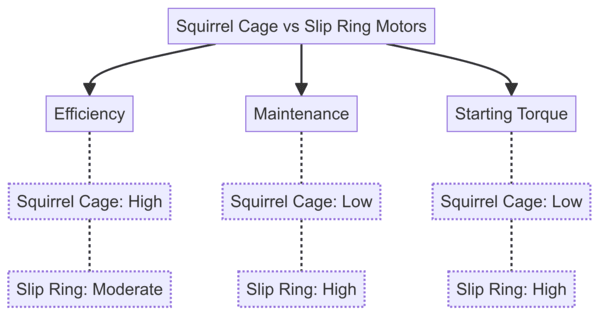

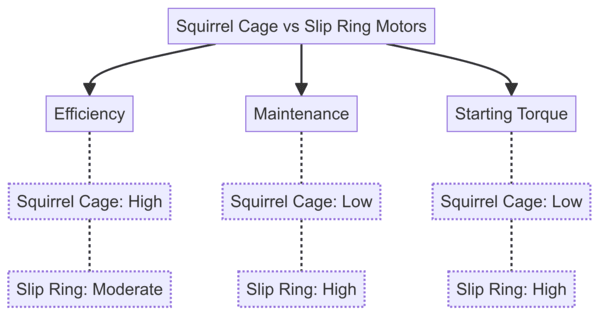

Comparisons

- Effectivity: Squirrel cage motors are typically extra environment friendly than slip ring motors.

- Upkeep: Squirrel cage motors require much less upkeep as a consequence of their less complicated building.

- Beginning Torque: Slip ring motors provide greater beginning torque and higher velocity management.

Development and Design

The development of a 3 part asynchronous motor entails numerous parts designed to optimize efficiency and sturdiness.

Stator Development

The stator is made up of a core constructed from laminated metal to cut back eddy present losses. It has slots the place the three-phase windings are positioned. These windings are sometimes product of copper or aluminum and are organized to create a rotating magnetic discipline when energized.

Rotor Development

The rotor will be both a squirrel cage or wound kind. The squirrel cage rotor consists of conductive bars embedded in a laminated metal core, related by finish rings. The wound rotor, however, has windings much like the stator, related to slide rings that permit for exterior resistance to be added.

Windings and Magnetic Area

The windings within the stator are essential for creating the rotating magnetic discipline. When a three-phase present flows by means of these windings, it produces a magnetic discipline that rotates across the stator. This rotating discipline induces a present within the rotor, inflicting it to show and produce mechanical movement.

Working Rules

Understanding the working ideas of three part asynchronous motors is essential to appreciating their performance and efficiency.

Induction Course of

The induction course of is key to the operation of those motors. When the stator’s rotating magnetic discipline cuts by means of the rotor, it induces an electromotive drive (EMF) within the rotor conductors. This induced EMF generates a present within the rotor, which in flip produces its personal magnetic discipline. The interplay between the stator and rotor magnetic fields generates torque, inflicting the rotor to rotate.

Slip and Synchronization

Slip is a vital idea in asynchronous motors. It’s outlined because the distinction between the synchronous velocity (the velocity of the rotating magnetic discipline) and the precise velocity of the rotor. Slip is critical for the induction course of to happen, because it creates the relative movement wanted to induce EMF within the rotor. The motor’s effectivity and efficiency are influenced by the slip, with optimum efficiency occurring at a sure slip share.

Torque Manufacturing

Torque manufacturing in a 3 part asynchronous motor is a results of the interplay between the stator and rotor magnetic fields. The magnitude of the torque depends upon the power of those fields and the slip. The motor’s torque-speed attribute curve reveals how the torque varies with velocity, highlighting totally different working areas reminiscent of beginning, peak torque, and steady operation.

Efficiency Traits

Three-phase asynchronous motors are valued for his or her efficiency traits, which embrace effectivity, speed-torque relationship, and energy issue.

Effectivity

The effectivity of an asynchronous motor is influenced by numerous components, together with design, building, and working situations. Excessive-quality supplies, precision engineering, and correct upkeep contribute to optimum effectivity. Losses within the motor, reminiscent of core losses, copper losses, and mechanical losses, must be minimized to boost effectivity.

Velocity-Torque Traits

The speed-torque attribute curve of a 3 part asynchronous motor illustrates the connection between the motor’s velocity and the torque it produces. This curve sometimes reveals excessive torque at low speeds (beginning torque), a peak torque at a sure slip, and a gradual lower in torque because the velocity approaches synchronous velocity. Understanding this curve helps in deciding on the best motor for particular purposes.

Energy Issue

The ability issue of an asynchronous motor is a measure of how successfully it converts electrical energy into mechanical energy. A excessive energy issue signifies environment friendly energy utilization, whereas a low energy issue suggests inefficiencies. Varied strategies, reminiscent of utilizing energy issue correction capacitors, can enhance the motor’s energy issue.

Beginning Strategies

Beginning strategies are essential for guaranteeing easy and environment friendly operation of three-phase asynchronous motors. Totally different strategies are used based mostly on the motor kind and utility necessities.

Direct On-Line (DOL) Beginning

DOL beginning is the best and commonest technique, the place the motor is immediately related to the facility provide. It affords a simple and cost-effective resolution however can lead to excessive inrush currents and mechanical stress on the motor.

- Benefits: Easy and cheap.

- Disadvantages: Excessive inrush present, mechanical stress.

Star-Delta Beginning

Star-delta beginning reduces the inrush present by initially connecting the motor windings in a star configuration, then switching to a delta configuration for regular operation. This technique is often used for motors with greater energy scores.

- Benefits: Lowered beginning present, decrease mechanical stress.

- Disadvantages: Extra advanced circuitry, transition time between star and delta.

Auto-Transformer Beginning

Auto-transformer beginning makes use of an auto-transformer to cut back the voltage utilized to the motor throughout startup, thereby limiting the inrush present. As soon as the motor reaches a sure velocity, the complete voltage is utilized.

- Benefits: Managed beginning present, appropriate for bigger motors.

- Disadvantages: Greater price, extra advanced setup.

Management and Upkeep

Correct management and upkeep are important for the dependable and environment friendly operation of three-phase asynchronous motors.

Management Strategies

Management strategies for these motors embrace variable frequency drives (VFDs) and mushy starters. VFDs permit exact management of motor velocity and torque by various the frequency and voltage of the facility provide. Delicate starters restrict the inrush present throughout startup, decreasing mechanical stress and enhancing motor lifespan.

Upkeep Practices

Common upkeep practices embrace inspecting and cleansing motor parts, checking electrical connections, lubricating bearings, and monitoring temperature and vibration ranges. Preventive upkeep helps in figuring out potential points early and guaranteeing steady operation.

Troubleshooting

Widespread issues with three part asynchronous motors embrace overheating, extreme noise, and vibration. Troubleshooting entails diagnosing the foundation trigger of those points, reminiscent of electrical faults, misalignment, or bearing put on, and implementing corrective measures.

Functions of Three-Section Asynchronous Motors

Three part asynchronous motors are utilized in a variety of purposes as a consequence of their versatility and reliability.

Industrial Makes use of

In industrial settings, these motors energy equipment reminiscent of pumps, compressors, conveyor methods, and followers. Their robustness and skill to deal with various masses make them best for heavy-duty purposes.

Business Makes use of

Business purposes embrace HVAC methods, elevators, and escalators, the place constant efficiency and effectivity are crucial. These motors are additionally utilized in business constructing automation methods.

Particular Functions

Particular purposes of three part asynchronous motors embrace electrical autos, renewable vitality methods, and marine propulsion. Their adaptability and efficiency traits make them appropriate for progressive and rising applied sciences.

Benefits and Disadvantages

Understanding the benefits and downsides of three part asynchronous motors helps in making knowledgeable selections for his or her use.

Execs

- Effectivity: Excessive effectivity in changing electrical energy to mechanical energy.

- Reliability: Strong building and low upkeep necessities.

- Versatility: Appropriate for a variety of purposes.

- Value-Efficient: Decrease preliminary and working prices in comparison with different motor sorts.

Cons

- Beginning Torque: Decrease beginning torque in comparison with another motor sorts.

- Energy Issue: Doubtlessly decrease energy issue, requiring correction strategies.

- Velocity Management: Restricted velocity management capabilities with out extra gear.

Future Tendencies and Improvements

The way forward for three part asynchronous motors is formed by technological developments and the demand for energy-efficient options.

Technological Developments

Current developments embrace using superior supplies, improved design strategies, and good monitoring methods. These improvements improve motor efficiency, reliability, and effectivity.

Vitality Effectivity Enhancements

Vitality effectivity is a key focus, with new motor designs and applied sciences aimed toward decreasing vitality consumption and minimizing losses. Laws and requirements are additionally driving the adoption of extra environment friendly motors.

Integration with Trendy Programs

Three part asynchronous motors are more and more built-in with fashionable management methods, reminiscent of IoT and AI-based monitoring options. These integrations allow predictive upkeep, distant monitoring, and enhanced efficiency optimization.

Conclusion

Three part asynchronous motors are a cornerstone of commercial and business purposes as a consequence of their effectivity, reliability, and flexibility. Understanding their building, working ideas, and efficiency traits is important for maximizing their potential.

As know-how continues to advance, these motors are poised to change into much more environment friendly and adaptable, assembly the evolving wants of assorted industries. The longer term holds thrilling prospects for three-phase asynchronous motors, pushed by improvements in supplies, design, and management methods.

For companies and engineers, staying knowledgeable about these developments shall be essential in harnessing the complete capabilities of those exceptional machines.